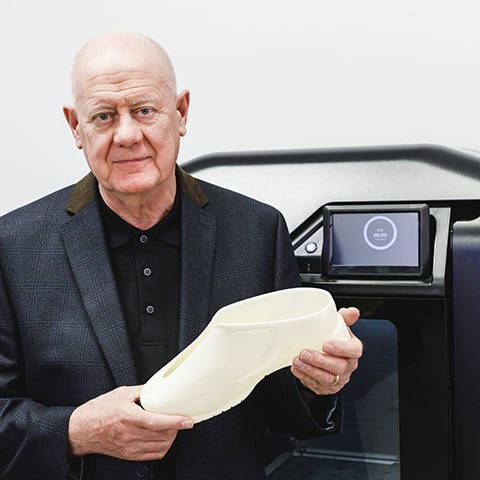

Storyboard: David Cawley

From the woodshop to the 3D lab: My journey as a maker

“My job as a creative is to keep up with technology as it changes. I always wanted to be ahead of the wave. The problems we face remain the same. It’s our means of solving problems that have changed.”

I’ve been a maker for as long as I can remember.

I’m one of seven kids and grew up in Manchester, United Kingdom. My hometown was the epitome of industrial. The sheer number of factories and foundries located there was astonishing. My whole family worked industrial jobs. My dad was a Sheet Metal Worker, and my uncles clocked in at the local engineering firms.

The high school I attended was one that prepared students for the realities of working and living in an industrial society. There was a clear and consistent emphasis on making things. Lucky for me, making things is something I’ve always understood.

Being a maker, I assimilated with ease into a culture defined by manufacturing. However, there was a sharp decline in manufacturing and industry somewhere in the early 1970s, and all the factories began to close.

Thankfully, I found myself on the back end of that particular cultural change. At the time, it seemed like my future was divided into two options: trade school or night school, and journeyman or craftsman.

I came into the craft of Pattern Making knowing that its practitioners were undervalued and underpaid. Patent makers are those in charge of making wooden models (patterns) that are used in foundries to assist in casting metal objects. During my early days, the discipline itself was going through a transition. This meant there would be a learning curve. Still, nothing could stop me.

What I was doing back then wasn’t too dissimilar from the concept of design thinking, really. Our job involved evaluating blueprints, deconstructing designs from the drawing office, and thinking of ways to transform an idea into something physical that has utility in the world.

My relationship to ArtCenter is a serendipitous one. Before I began teaching 3D printing here, I had never heard of the College, but when I was told that ArtCenter was in the market for someone to oversee the 3D lab, I jumped at the opportunity. One of the things I responded to immediately about ArtCenter was that most, if not all, of the faculty were working professionals. By the time I became an ArtCenter faculty member, I had shifted from Pattern Making into Model Making, arriving at the juncture of 3D printing and rapid prototyping.

When I first arrived at ArtCenter, I was the manager of the College’s 3D lab. We had everything the students needed: laser cutters, digital scanners, you name it. With all of this enticing new tech at our fingertips, I nevertheless implored my students not to lose touch with the essence of their craft, reminding them that you can learn as much in the woodshop as you can using a 3D printer, and nothing substitutes for the rough, tactile nature of our practice. There’s nothing quite like feeling the materials in your hands as you work.

My job as a creative is to keep up with technology as it changes. I always wanted to be ahead of the wave. The problems we face remain the same. It’s our means of solving problems that have changed.

Though ArtCenter is a school that is always looking to the future, I still try to instill in my students an emphasis on the value of tradition. Sometimes, I’ll show them a piece from my vast collection of old tools just to illustrate how far we’ve come. As forward-thinking as ArtCenter students generally are, they are still fascinated with the history of our trade. ArtCenter teaches you to appreciate things that are well made, be it by hand or by computer.

We live in a time without limits. 3D printing feels like more than just a hobby. At this point, it’s practically a symptom of the new industrial revolution. It’s easy to forget that the technology was only really commercialized in the 1980s. That means it’s a new way of doing things – and a disruptive way, to say the least.

You have to ask yourself these questions: How do you push the pendulum forward while still paying homage to the past? How important are aesthetics, really? What is the value of creating something by hand, and how do you carry that philosophy into our increasingly digital world?

The power of our craft transcends generational differences. Whether you’re in the shop or in the lab, the questions you will face are the same. The chisel and plane offer a different, but equally valuable, counterpart to the magic of a 3D printer.

David Cawley

Director, 3D, Model and South Campus Shops

My job as a creative is to keep up with technology as it changes. I always wanted to be ahead of the wave. The problems we face remain the same. It’s our means of solving problems that have changed.